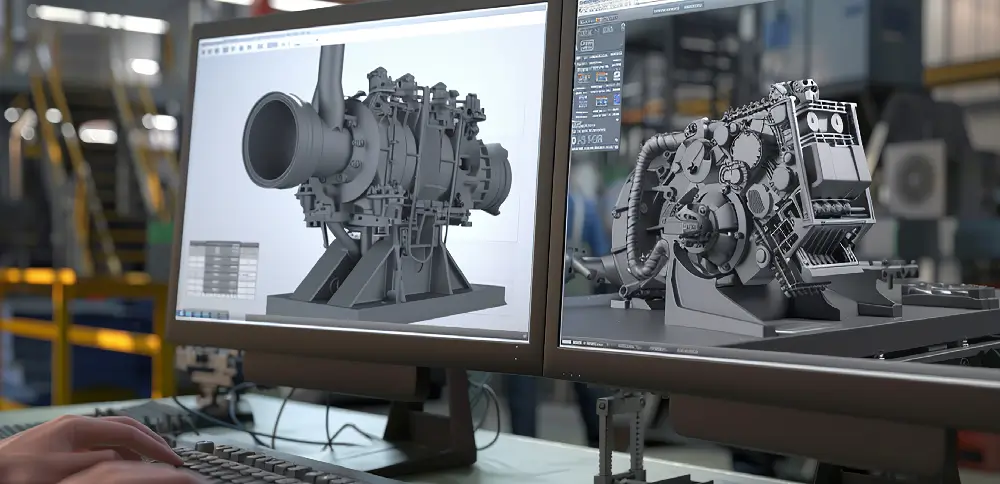

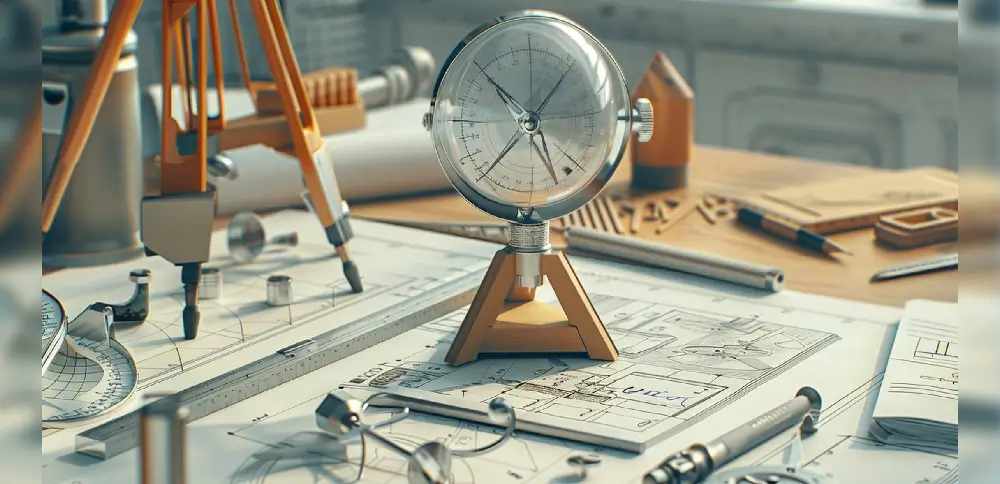

2D drawings provide flat, detailed representations of mechanical parts, showing multiple views like front, top, and side to convey dimensions and features. In contrast, 3D drawings offer a more realistic, visual model of the component, displaying it in three dimensions to help with understanding complex geometries.

Design for Manufacturing and Assembly (DFMA) analysis focuses on optimizing product design to simplify manufacturing processes and ease assembly. It aims to reduce production costs, minimize part count, and improve overall efficiency by ensuring designs are compatible with manufacturing capabilities.

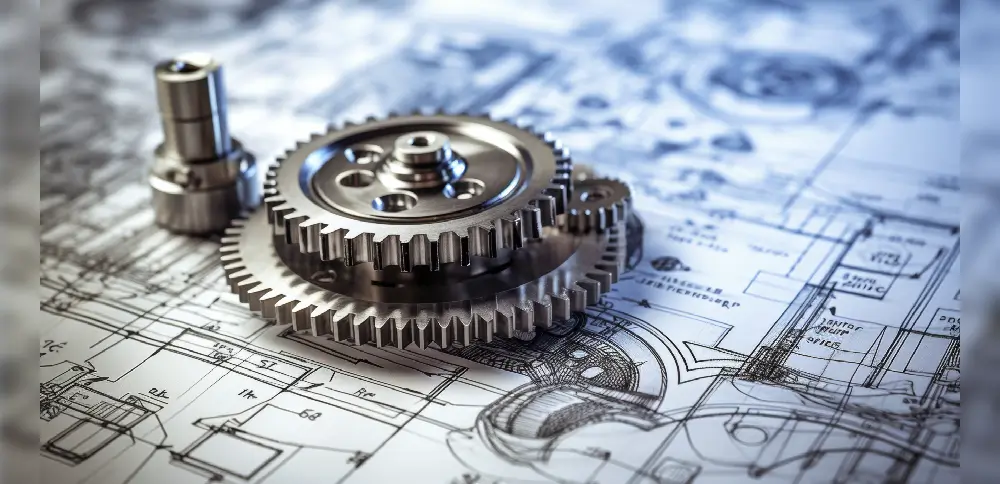

Detailed dimensional and geometric analysis ensures that mechanical parts meet precise size, shape, and tolerance requirements. It involves evaluating critical dimensions, geometric features like flatness, perpendicularity, and circularity, and how these elements interact with other components.

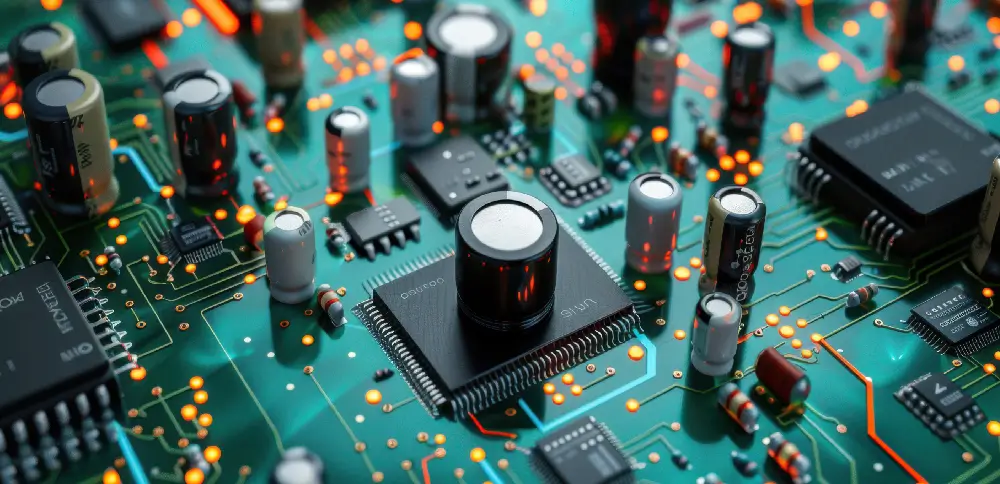

Electronic and electrical analysis involves evaluating circuits, components, and systems to ensure proper functionality, efficiency, and safety. It includes assessing voltage, current, resistance, and signal integrity, as well as analyzing power distribution and electromagnetic interference.

Manufacturability analysis evaluates a product's design to ensure it can be produced efficiently, cost-effectively, and with minimal production issues. This process assesses factors like material selection, part complexity, tooling requirements, and manufacturing processes.

Material and surface analysis examines the properties of materials and their surface finishes to ensure they meet performance, durability, and functional requirements. It involves evaluating factors like strength, wear resistance, corrosion resistance, and surface texture.

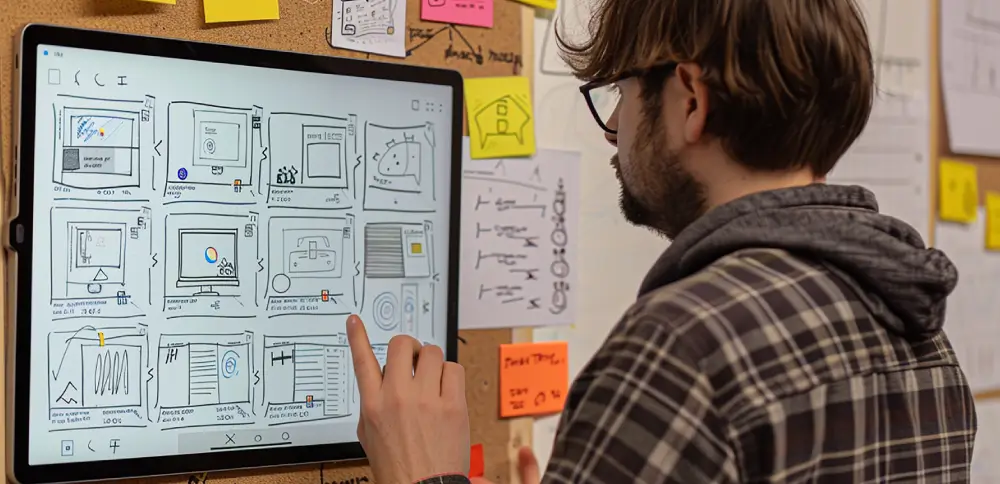

Prototyping is a critical phase in product development, allowing designers and engineers to create a functional model of a product before full-scale production. It helps in testing the design, identifying potential issues, and making necessary improvements.

Quality control inspection is a vital process in ensuring that products meet the required standards and specifications before they reach the market. It involves thorough examination and testing of materials, components, and finished goods to detect any defects or deviations.